Products

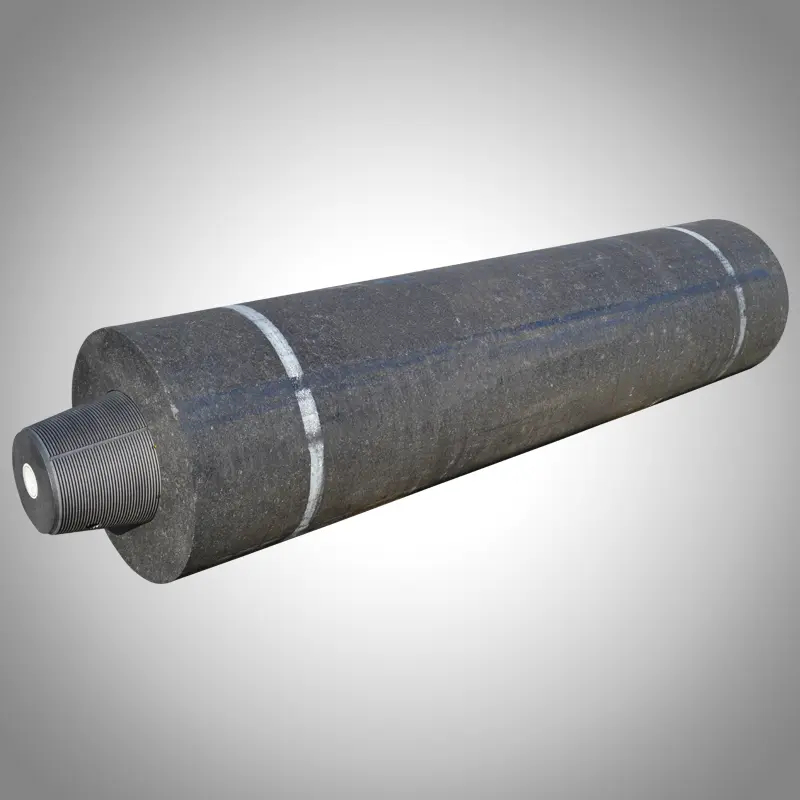

Calcined Petroleum Coke (CPC Coke)

•Coke filter material is bituminous coal under the condition of the air, heated to 950-950 ℃, after drying, pyrolysis, molten, bonding, solidification and contraction phase made finally.

•High mechanical strength, well developed porous structure, good adsorption performance, long life cycle, strong sewage capability and filtration speed.

•Coke in addition to a large number of used in ironmaking and smelting non-ferrous metal (metallurgical coke), also used in casting, chemical industry, calcium carbide and ferroalloy.

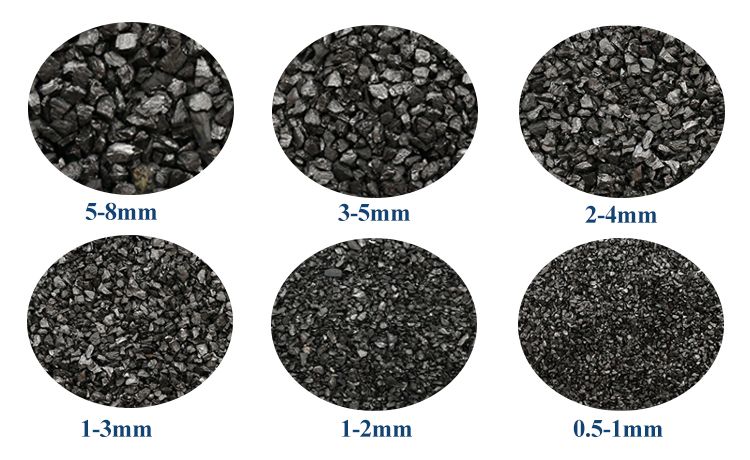

Calcined Petroleum Coke Specifications

| Compressive Strength |

600(kgf)

|

Moisture

|

1%

|

|

Abrasion Resistance

|

0.26

|

Volatile Matter

|

1%

|

| Sulphur Content

|

0.5% |

Fixed Carbon |

95%

|

|

Ash

|

2%

|

Size |

1-3 3-5 5-8 8-10 mm etc. |

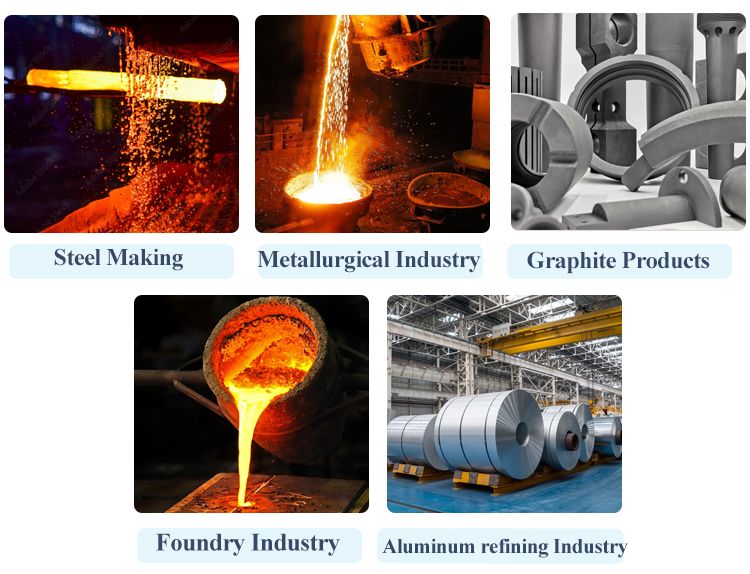

Application

1.Used for steel making, can improve the Carbon content in steel-melting and Ductile iron foundry.

2.Mainly used in steelmaking in electrical stove, screening water, shipbuilding sandblast to remove rust.

3.Can reduce the cost of steelmaking effectively by replacing the traditional petroleum coke of carburant.

Packaging & Shipping

1.Used for steel making, can improve the Carbon content in steel-melting and Ductile iron foundry.

2.Mainly used in steelmaking in electrical stove, screening water, shipbuilding sandblast to remove rust.

3.Can reduce the cost of steelmaking effectively by replacing the traditional petroleum coke of carburant.

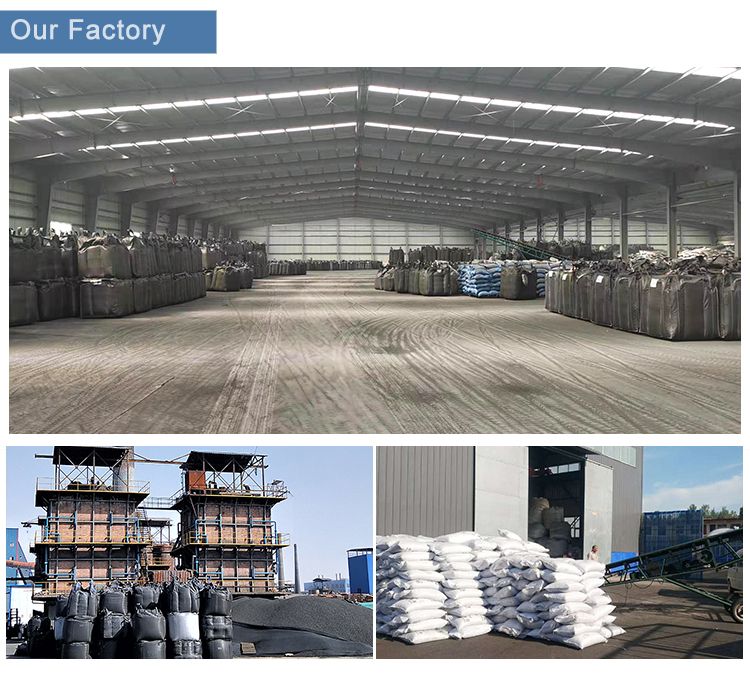

Our factory

Our Laboratory