Products

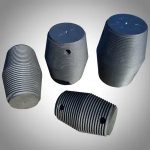

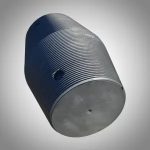

GRAPHITE ELECTRODE NIPPLES

1.Low electric resistance

2. High density

3. Good electrical conductivity

4. High anti-oxidation capability

5. Precise machining accuracy

6. Low sulphur and low ash, not give steel second time impurity

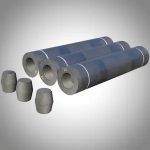

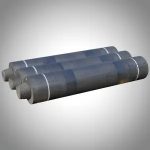

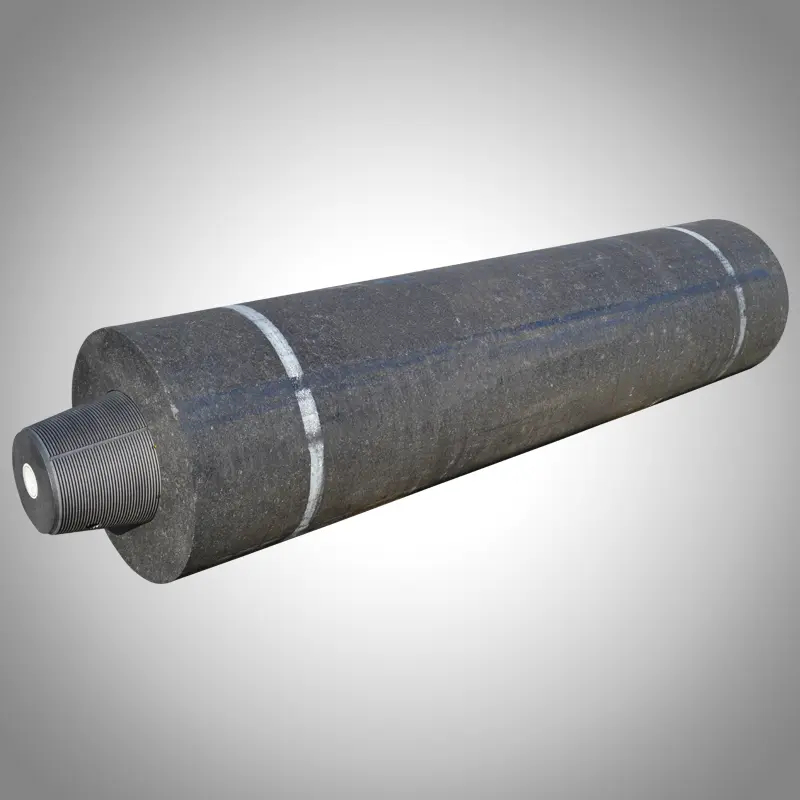

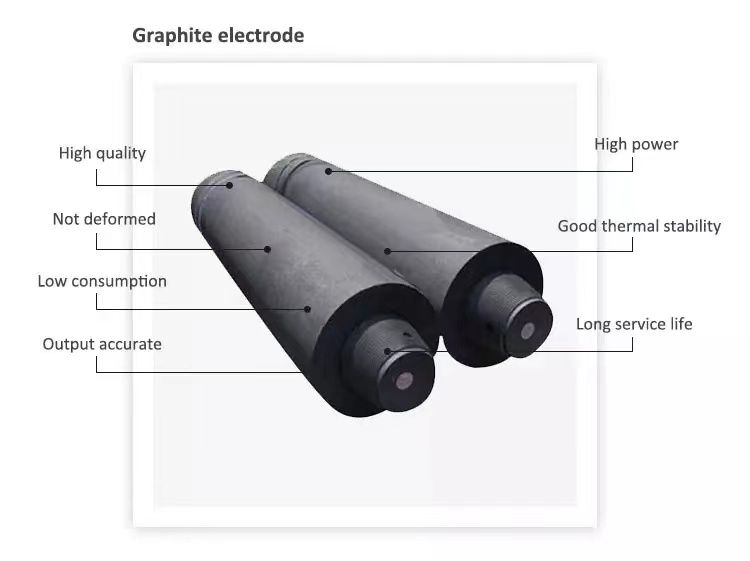

The graphite electrode will be a high-temperature graphite conductive material, the core of which consists of petroleum coke, tar coke as a filler, coal tar as a binder. We produce graphite electrodes and nipples to them. Graphite electrodes are characterized by low resistance, good electrical conductivity and thermal conductivity, high resistance to oxidation and thermal shock, high mechanical strength, etc.According to its high quality and low quality, it can be divided into ordinary power graphite electrode, high power graphite electrode and ultra high power graphite electrode.

Features of Graphite electrodes

1.Low electric resistance

2. High density

3. Good electrical conductivity

4. High anti-oxidation capability

5. Precise machining accuracy

6. Low sulphur and low ash, not give steel second time impurity

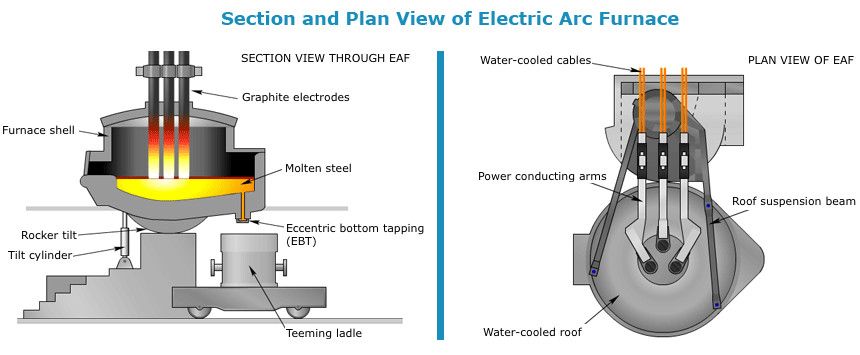

Application of Graphite electrodes

Graphite electrodes are used mainly in ladle furnaces,electric-arc furnace steelmaking,Yellow phosphorus furnace , Industrial silicon furnace or melting copper. They are presently the only products available that have the high levels of electrical conductivity and the capability of sustaining the extremely high levels of heat generated in this demanding environment.High Quality Needle Coke in HP&UHP graphite electrode,ensure the electrode application is perfect. Graphite electrodes are also used to refine steel in ladle furnaces and in other smelting processes.

1.mainly used for electric arc furnace (EAF) steel production;

2.for ore-thermal furnace; for the resistance furnace;

3.for the production of profiled graphite products;

4.for the production of shaped graphite products;

5.Also can used For a resistor furnace;

6.For the production of graphite shaped products;

Specification

| Name | Unit | Nominal Diameter | ||||||

| UHP Ultra-High-Power | HP Superstrong | RP Conventional Power | ||||||

| ≤Φ400 | ≥Φ450 | ≤Φ400 | ≥Φ450 | ≤Φ300 | ≥Φ350 | |||

| Resistivity | Electrode | ΜΩ · m | ≤5.5 | ≤6.5 | ≤8.5 | |||

| Nipple | ≤4.5 | ≤5.5 | ≤6.5 | |||||

| Flexural Strength | Electrode | MPa | ≥11.0 | ≥10.5 | ≥9.8 | ≥8.5 | ≥7.0 | |

| Nipple | ≥20.0 | ≥16.0 | ≥15.0 | |||||

| Elastic Modulus | Electrode | GPa | ≤14.0 | ≤12.0 | ≤9.3 | |||

| Nipple | ≤18.0 | ≤16.0 | ≤14.0 | |||||

| Density | Electrode | g / cm3 | ≥1.66 | ≥1.67 | ≥1.62 | 1.6 | ≥1.53 | ≥1.52 |

| Nipple | ≥1.75 | ≥1.73 | ≥1.69 | |||||

| Coefficient Of Thermal Expansion | Electrode | 10-6 / ℃ | ≤1.5 | ≤2.4 | ≤2.9 | |||

| Nipple | ≤1.4 | ≤2.2 | ≤2.8 | |||||

| ASH | % | ≤0.3 | ≤0.3 | ≤0.5 | ||||

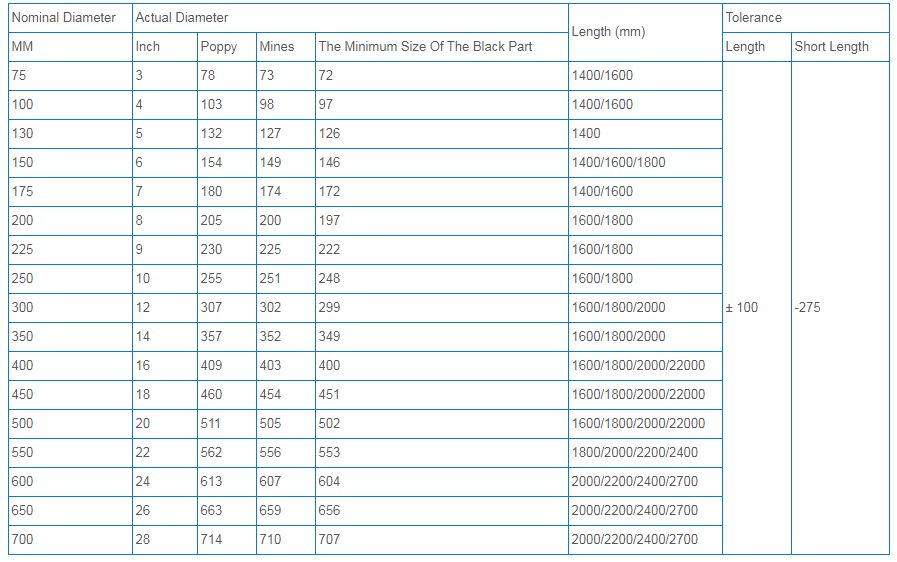

The Length & Diameter & Permissible Deviation of Graphite Electrode

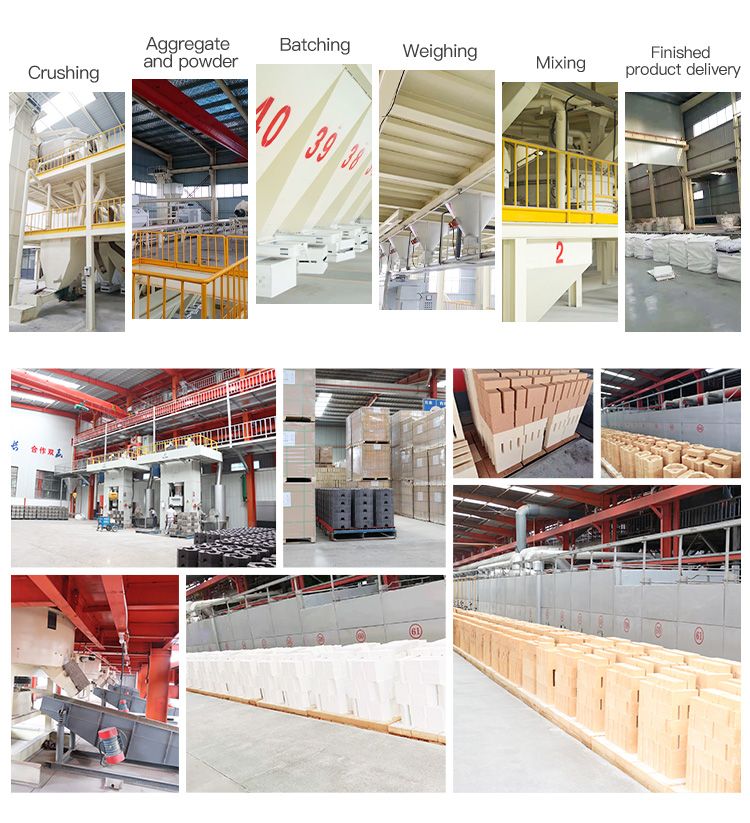

Production workshop