Khoom

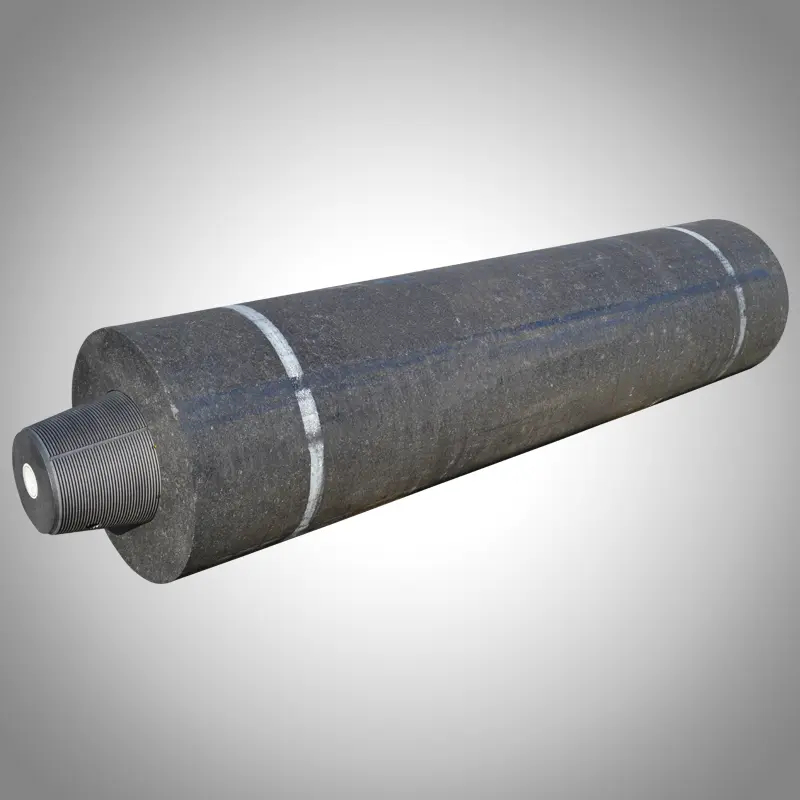

Graphite electrode tsis kam, ntom ntom ntom

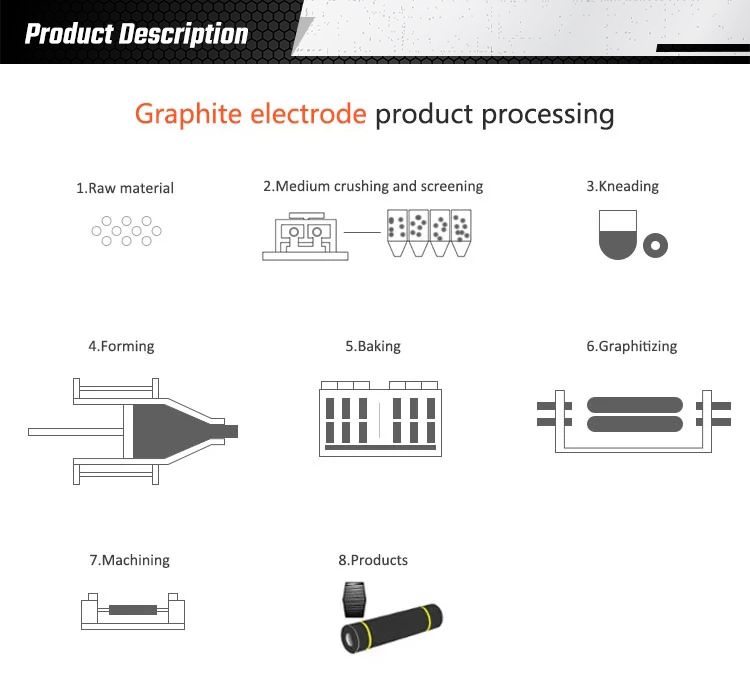

Graphite electrodes yog cov cim los ntawm kev tiv thaiv qis, zoo ua haujlwm, muaj zog, nws tuaj yeem muab faib ua cov hluav taws xob zoo li qub hluav taws xob, muaj zog Graphite electrode thiab ultra lub zog loj graphite electrode.

Qhov Zoo

1.anti-oxidation kev kho mob rau kev ntev.

2.Qhov-purity, siab-ntom, muaj zog tshuaj ruaj khov.

3.Highy machining raug, zoo nto moo.

4.High tshuab kho tshuab zog, tsawg hluav taws xob tsis kam.

5..resant kom tawg & spalling. 6.Qhov tsis kam rau oxidation thiab thermal poob siab.

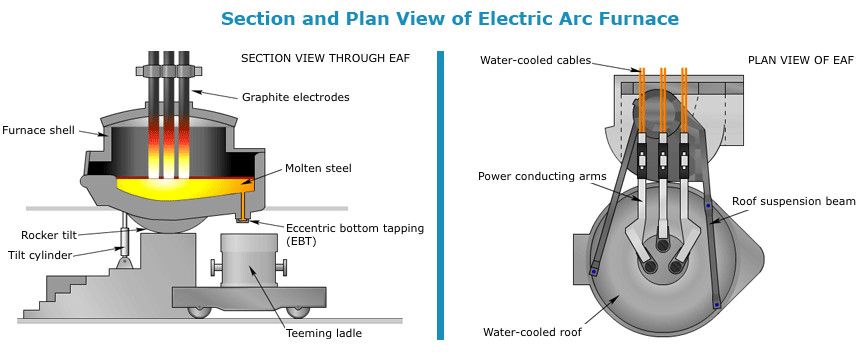

Cov Ntawv Thov

1.Cov cua arc ntawm hluav taws xob arc rauv. Graphite cov ntawv hluav taws xob feem ntau siv nyob rau hauv cov thee-smelting fais rauv taws.

2.Cov ib kaw arc.

3.Rau lub cub tawg.

4.Txhua cov khoom lag luam graphite.

Graphite Electrode Varm kuj tseem siv rau kev ua hauv ntau crucibles, duab, nkoj thiab cov khoom siv cua sov thiab cov khoom siv cua sov thiab cov khoom siv cua sov thiab cov khoom siv cua sov thiab cov khoom siv cua sov thiab cov khoom siv cua sov thiab cov khoom siv cua sov thiab cov khoom siv cua sov thiab cov khoom siv cua sov. Piv txwv li, hauv cov iav quartz iav kev lag luam, rau txhua qhov kev tsim khoom ntawm 1 m yog xav tau, rau txhua lub quartz cib ntawm 1 tuj nws yog qhov tsim nyog yuav tsum tau haus 100 kg ntawm graphite electrode.

Kev qhia tshwj xeeb

Cov txiv mis hluav taws xob: graphite electrodes thiab mis muaj qhov zoo ntawm lub zog siab, tsis yooj yim tawg, thiab kev hla dhau tam sim no thiab muaj kev ploj mus tam sim no.

| Lub npe | Ib yam | Nominal diam | ||||||

| Uhp ultra-high-hwj chim | HP Superstrong | Rp lub zog siv hluav taws xob | ||||||

| ≤φوH00 | ≥ Sawm lij | ≤φوH00 | ≥ Sawm lij | ILTM300 | ≥ ATTHAXT350 | |||

| Resiveivity | Khoom siv hluav taws xob | M | 50,5 | ≤6.5 | ≤8.5 | |||

| Lub txiv mis | ≤4.5 | 50,5 | ≤6.5 | |||||

| Lub zog flexural | Khoom siv hluav taws xob | MPa | ≥11 | ≥10.5 | ≥9.8 | ≥8.5 | ≥7.0 | |

| Lub txiv mis | ≥20.0 | ≥16.0 | ≥15.0 | |||||

| Elastic modulus | Khoom siv hluav taws xob | GPA | ≤14.0 | ≤12.0 | ≤9.3 | |||

| Lub txiv mis | O≤18.0 | E≤16.0 | ≤14.0 | |||||

| Ceev | Khoom siv hluav taws xob | g / cm3 | ≥1.66 | ≥1.67 | ≥1.62 | 1.6 | ≥1.53 | ≥1.52 |

| Lub txiv mis | ≥1.75 | ≥1.73 | ≥1.69 | |||||

| Coefficient ntawm thermal expansion | Khoom siv hluav taws xob | 10-6 / ℃ | ≤1.5 | I≤2.4 | ≤2.9 | |||

| Lub txiv mis | I≤1.4 | ≤2.2 | ≤2.8 | |||||

| Txhos | % | I≤0.3 | I≤0.3 | I≤0.5 | ||||

Kev Lag Luam Kev Lag Luam Kev Lag Luam Kev Lag Luam

| Kuj (μω.m) | 4 - 9 micro |

| Pom meej ntom ntom (g / cm³) | 1.58 - 1.76 G / CC |

| FLEXURAL HEEV (N / ㎡) | 9.5-11.0 MPA |

Lwm tus cwj pwm

| Qhov chaw ntawm keeb kwm | NwsBEI HANDAN, Suav |

| Hom Lub Npe | heyuan |

| Tus Qauv Qauv | Rp, HD, HP, SHP, UHP |

| Ntaus | Cov Hluav Taws Xob Thaiv |

| Daim ntawv thov | Hlau Ua |

| Qho ntev | 1600 ~ 3000mm |

| Teem nqi | UHP (ultra siab zog) |

| Thermal nthuav dav | 1.5 - 2.8 X10-6 |

| Xim | Xim dub |

| Daim ntawv thov | Fais arc rauv (EAF) steel ntau lawm |

| Qhov loj | Customized loj |

| Ceev | ≥1.52 |

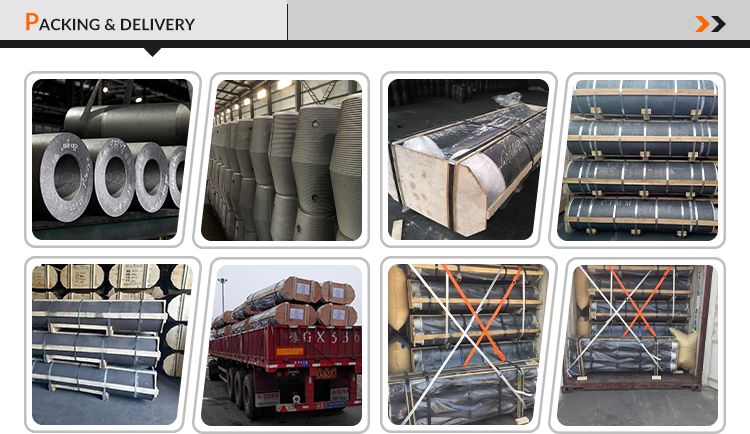

Ntim thiab xa khoom

| Xov Xwm Ntim | Txheem export ntim lossis raws li cov neeg yuav tsum tau ua |

Muab khoom muaj peev xwm

| Muab khoom muaj peev xwm | 100 tuj / tons ib hnub rongsheng electrode graphite |

Cov ntsiab lus ntau lawm

Ntim & Xa Tawm