Khoom

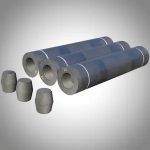

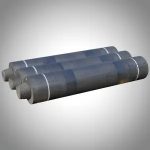

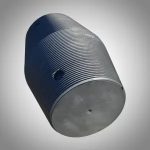

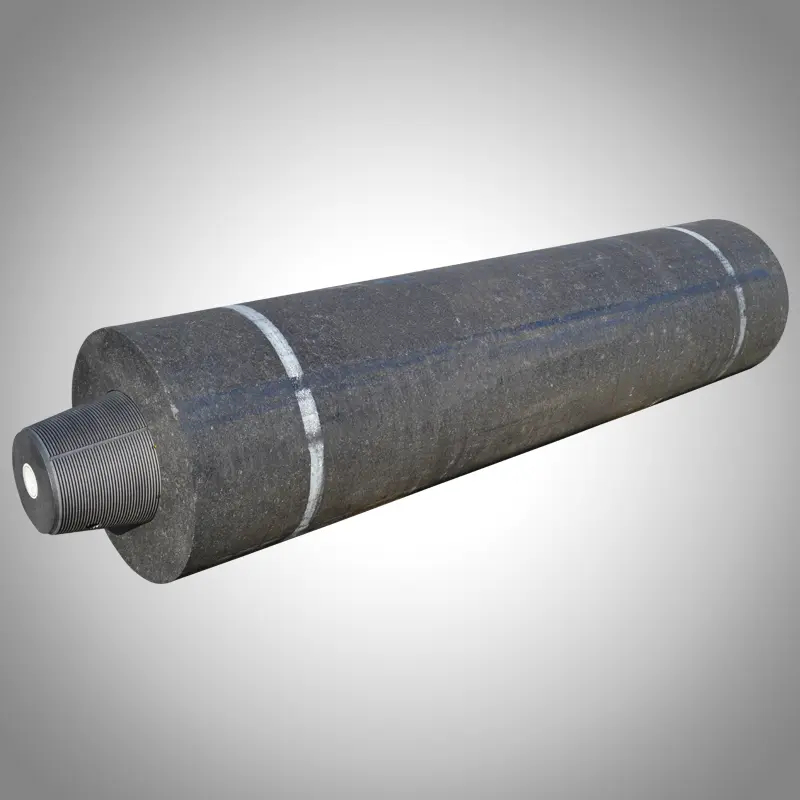

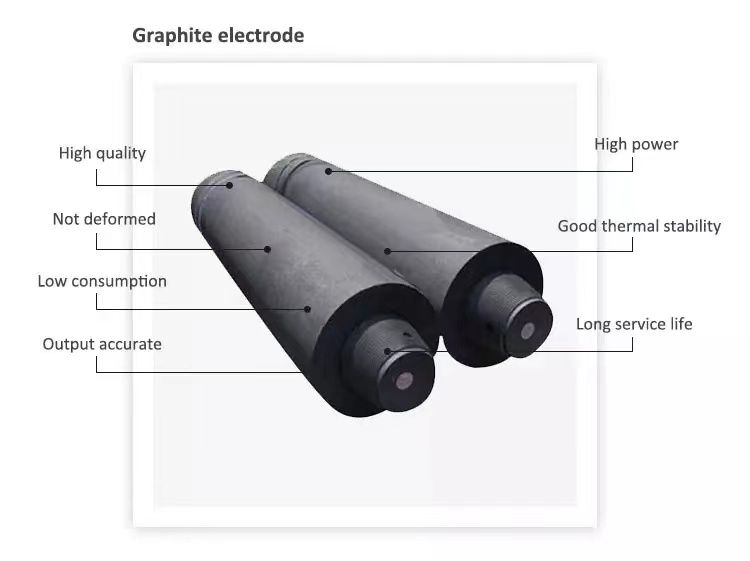

Graphition Electrode

1.low hluav taws xob tiv thaiv

2. Kev ntom ntom

3. Kev ua hluav taws xob zoo

4. Cov peev txheej siab los tiv thaiv oxidation

5. Mob Machining Qhov Tseeb

6. Tsawg sulfur thiab cov tshauv qis, tsis muab cov steel thib ob Irurity

Cov graphite electrode yuav yog cov khoom siv ntawm cov roj ntsha hnyav, cov nqaij nyuj roj av uas muaj cov muab tub lim, txhaws cov tar li ib phau. Peb tsim cov duab hluav taws xob graphite thiab mis rau lawv. Graphite electrodes yog cov cim los ntawm kev tiv taus hluav taws xob qis, muaj zog, muaj zog ntxiv, nws tuaj yeem muab faib ua cov hluav taws xob zoo li qub hluav taws xob, muaj zog Graphite electrode thiab ultra lub zog loj graphite electrode.

Cov nta ntawm graphite electrodes

1.low hluav taws xob tiv thaiv

2. Kev ntom ntom

3. Kev ua hluav taws xob zoo

4. Cov peev txheej siab los tiv thaiv oxidation

5. Mob Machining Qhov Tseeb

6. Tsawg sulfur thiab cov tshauv qis, tsis muab cov steel thib ob Irurity

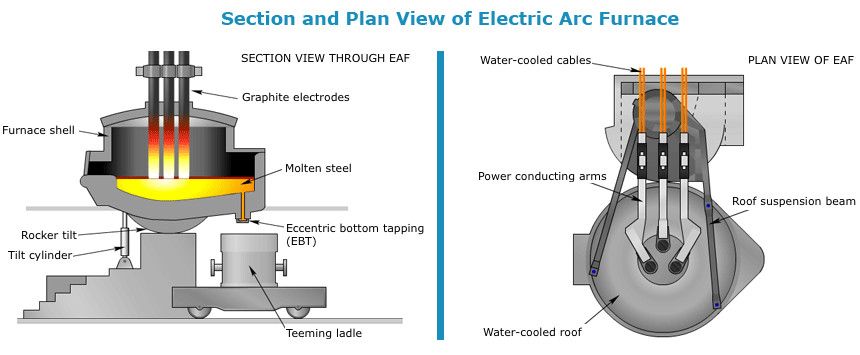

Daim ntawv thov ntawm Graphite Ectrodes

Graphite electrodes yog siv feem ntau nyob rau hauv chav tsev so hauv tsev ua kom huv, daj phosphorus rauv, muaj silicon rauv lossis melting tooj liab. Lawv tam sim no tsuas yog cov khoom lag luam uas muaj cov hluav taws xob siab thiab cov muaj peev xwm ntawm kev txhawb nqa hp & UHP graphite electrode, kom ntseeg tau qhov kev thov electrode yog zoo meej. Graphite hluav kuj tseem siv los ua kom ua kom ua cov hlau nyob hauv chav tsev ua kom sov thiab hauv lwm cov txheej txheem smelting.

1.Mainly siv rau hluav taws xob arc rauv (EAF) ntau lawm;

2.Or are-Thermal rauv; rau cov referance rauv;

3.Txawm cov khoom lag luam graphite graphite;

4. Cov khoom lag luam ntawm cov khoom lag luam graphite;

5.Asso tuaj yeem siv rau cov cua sov resistor;

6.roo cov khoom tsim ntawm graphite cov khoom lag luam;

Kev qhia tshwj xeeb

| Lub npe | Ib yam | Nominal diam | ||||||

| Uhp ultra-high-hwj chim | HP Superstrong | Rp lub zog siv hluav taws xob | ||||||

| ≤φوH00 | ≥ Sawm lij | ≤φوH00 | ≥ Sawm lij | ILTM300 | ≥ ATTHAXT350 | |||

| Resiveivity | Khoom siv hluav taws xob | M | 50,5 | ≤6.5 | ≤8.5 | |||

| Lub txiv mis | ≤4.5 | 50,5 | ≤6.5 | |||||

| Lub zog flexural | Khoom siv hluav taws xob | MPa | ≥11 | ≥10.5 | ≥9.8 | ≥8.5 | ≥7.0 | |

| Lub txiv mis | ≥20.0 | ≥16.0 | ≥15.0 | |||||

| Elastic modulus | Khoom siv hluav taws xob | GPA | ≤14.0 | ≤12.0 | ≤9.3 | |||

| Lub txiv mis | O≤18.0 | E≤16.0 | ≤14.0 | |||||

| Ceev | Khoom siv hluav taws xob | g / cm3 | ≥1.66 | ≥1.67 | ≥1.62 | 1.6 | ≥1.53 | ≥1.52 |

| Lub txiv mis | ≥1.75 | ≥1.73 | ≥1.69 | |||||

| Coefficient ntawm thermal expansion | Khoom siv hluav taws xob | 10-6 / ℃ | ≤1.5 | I≤2.4 | ≤2.9 | |||

| Lub txiv mis | I≤1.4 | ≤2.2 | ≤2.8 | |||||

| Txhos | % | I≤0.3 | I≤0.3 | I≤0.5 | ||||

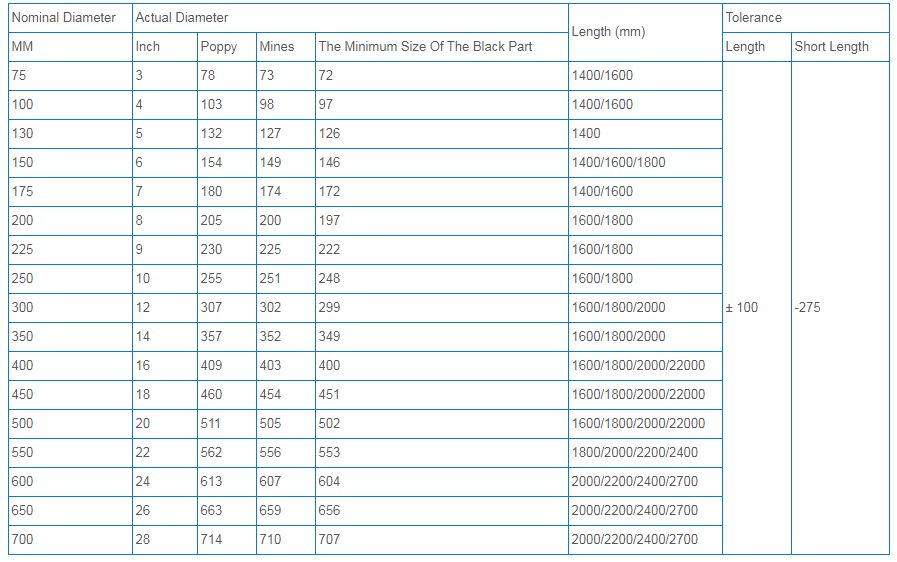

Qhov ntev & txoj kab uas hla thiab tso cai sib txawv ntawm graphite electrode

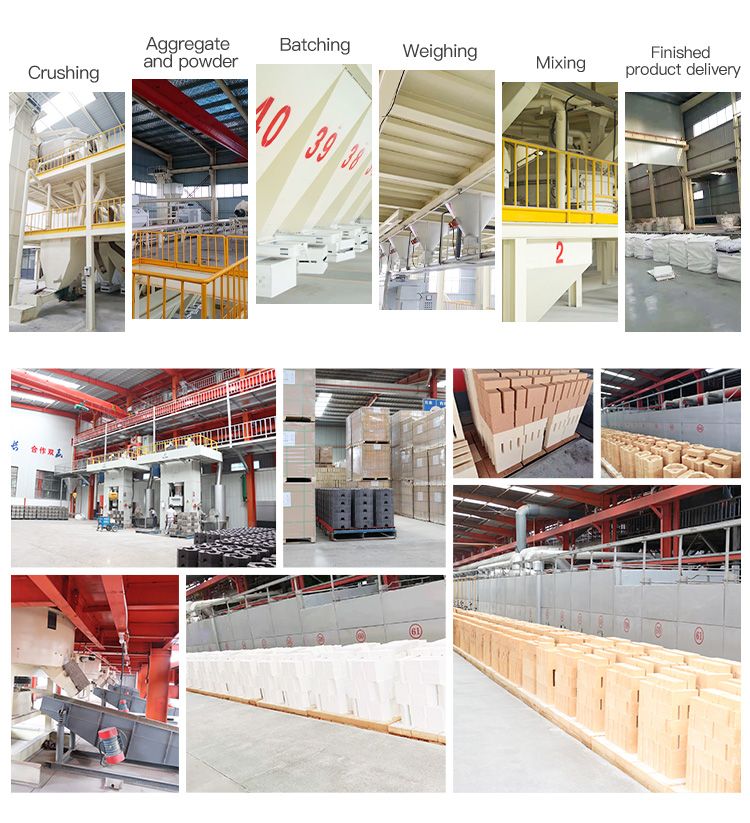

Ntau lawm Rhiav