Khoom

UHP Graphite electrode

Qhov Zoo

1.anti-oxidation kev kho mob rau kev ntev.

2.Qhov-purity, siab-ntom, muaj zog tshuaj ruaj khov.

3.Highy machining raug, zoo nto moo.

4.High tshuab kho tshuab zog, tsawg hluav taws xob tsis kam.

5..resant kom tawg & spalling.

6.Qhov tsis kam rau oxidation thiab thermal poob siab.

Daim ntawv thov

1.Txhua Arc riveraceto steelmaking.

2.formine Thermoelectric rauv rau kev tsim cov ferroalloy, silicon ntshiab, tooj liab phosphorus, tooj liab dej, calcium carbide, thiab lwm yam.

3.Resistance Rauv

| UHP Graphite electrode | ||

| Khoom muaj | ib yam | Sau nqi pes tsawg |

| Ceev ntom | g / cm3 | 1.68-1.78 |

| Kev tsis kam | m | 5.5 |

| Cov ntsiab lus tshauv | % | 0.2-0.3 |

| Lub zog flexural | MPa | 10.5-11 |

| Elastic modulus | GPA | 14 |

Cov khoom siv raw

Ua los ntawm cov khoom zoo tsawg cov hmoov tshauv qis, xws li roj av coke, koob coke thiab thee lub suab.

Qhov Zoo

Ua los ntawm cov khoom zoo tsawg cov hmoov tshauv qis, xws li roj av coke, koob coke thiab thee lub suab.

Nta

1.Thov kev tiv thaiv

2.good hluav taws xob conductivity

3.low tshauv

4.Compact qauv

5.Yog anti oxidation thiab high tshuab zog

Yog li nws yog cov khoom siv zoo tshaj plaws rau hluav taws xob arc rauv thiab smelting rauv.

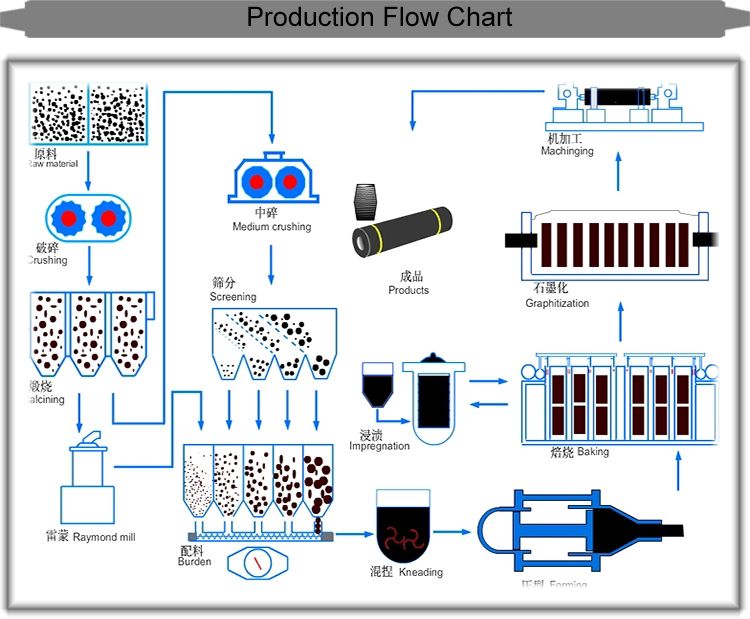

Cov txheej txheem ntau lawm

Calcining, Burring, sib sau, ci thiab siab imprists, graphitization ces cov khoom siv cnc machining.such ntawm cov khoom ntiag tug.

Yuav ua li cas txo qis

1.the Electrode tus tuav yuav tsum tau tuav hauv qhov chaw dhau ntawm cov kab kev ruaj ntseg ntawm cov yas sab saum toj; lwm yam, lub electrode yuav tsum tau ntxuav kom huv si, tus Lub tsho ua kom tsho ntawm tus tuav yuav tsum zam ntawm cov dej xau.

2.Txoj kev ua rau cov laj thawj nws muaj kev sib txawv hauv cov kev sib tshuam hluav taws xob hauv electrode, tsis txhob siv lawv kom txog thaum cov kis tau tshem tawm.

3.Yog hais tias muaj kev ploj ntawm Nipping Bolt thaum txuas cov hluav taws xob, nws yog qhov tsim nyog kom ua tiav lub txiv mis ntsia liaj qhov rooj.

4.Qhov kev thov ntawm electrode yuav tsum zam ntawm kev ua haujlwm hauv kev ua haujlwm, tshwj xeeb, cov gr.uptaws, cov gr.uple ntawm cov txuas nrog kom tiv thaiv kev tawg.

5.When them cov ntaub ntawv rau lub cub tawg, cov ntaub ntawv ntau yuav tsum tau them rau qhov chaw ntawm cov kev cuam tshuam ntawm cov cub hluav taws xob ntawm cov hluav taws xob.

6.Cov ntaub ntawv loj ntawm cov ntaub ntawv loj uas yuav tsum zam rau ntawm cov stacking hauv qab ntawm cov electrodes thaum smeltings ntawm kev siv electrode, lossis txawm tawg.

7.Txhob ntawm kev sib tsoo lub cub tawg thaum nce lossis nqis cov electrodes, uas tej zaum yuav ua rau cov electrode kev puas tsuaj.

8.Nws tsim nyog los tiv thaiv tus hlau slag los ntawm splashing rau splashing rau cov xov ntawm cov electrodes lossis txiv mis khaws cia rau hauv lub smelting site, uas tej zaum yuav ua rau qhov kev puas tsuaj ntawm cov xov.