Wax soo wadaban

Caabbinta korantada ee garaafka ee korantada oo hooseeya, cufnaanta sare

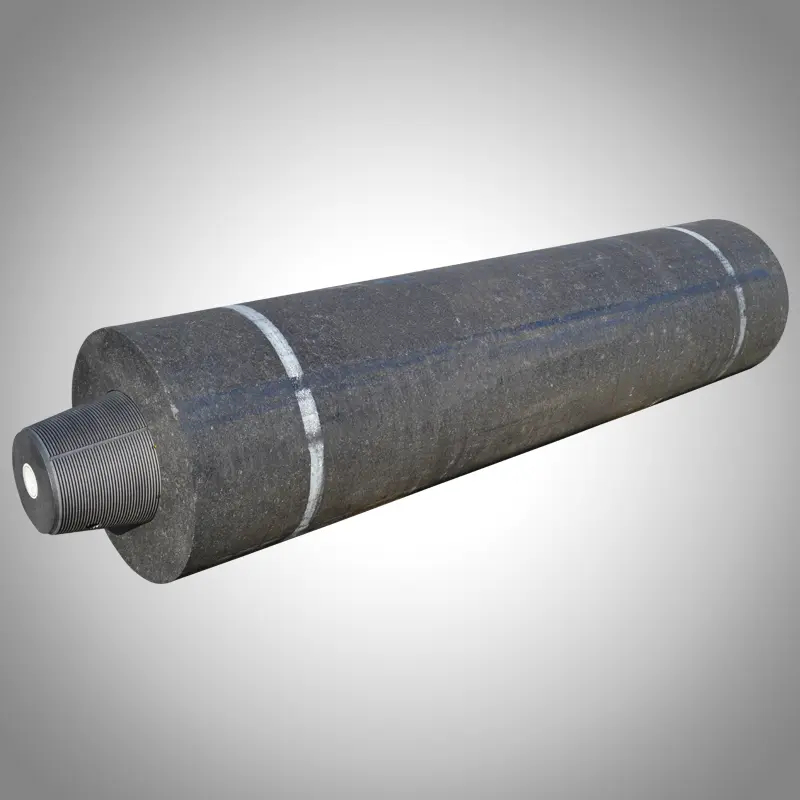

Cilmiga cudurka garaafka waxaa lagu gartaa iska caabbinta hooseeya, qabashada korantada wanaagsan iyo wanaagga kuleylka, iska caabbinta heerkulka, iyadoo loo qaybin karo koronto-dhaliye oo caadi ah, awood sare Koobka korantada ee garaafka gacanta.

Faa'iidooyinka

1. Bixitaanka si loogu daweeyo cimriga dheer.

2.Wax-daahir, cufnaanta sare, xasilloonida kiimikada adag.

3.Kuthalgh farsamo-xumeyn saxsanaanta, Dhamaadka dusha sare ee sare.

4.High xoog farsamo, iska caabbinta korantada oo hooseeya.

5.Maxeeyuhu inuu jajabiyo & isbadal. 6.Waxaad u adkeysaa caabbinta oksikada iyo shoogga kuleylka.

Codsiyada

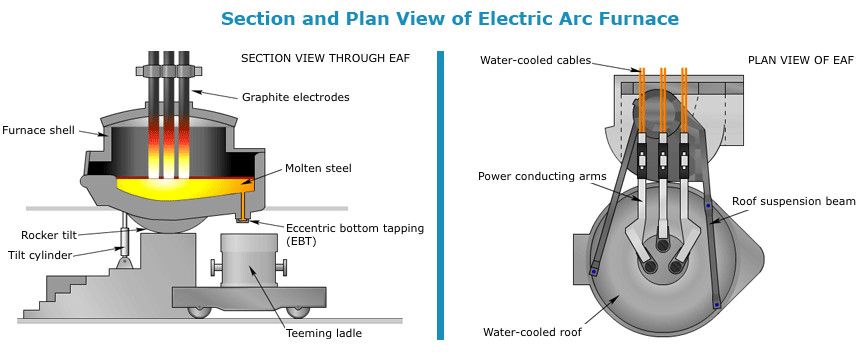

1. Fooloda ARC ee Footada ARC ee korantada. Qalabka cudurka garaafka ee garaafka ayaa inta badan loo isticmaalaa foornada korantada-dhuxusha.

2.Waxaan xidhxidhay.

3.Waayo foornada iska caabinta ah.

4.Waa wax soo saarka alaabooyinka qaababka garaaca.

Buug-gacmeedka suufka ah ayaa sidoo kale loo isticmaalaa in lagu hawlgalo ka baaraandegida qudhmooyinka kala duwan, qaababka, doomaha iyo waxyaabaha kuleylka iyo waxyaabaha kale ee garaafka. Tusaale ahaan, warshadaha dhalada ee rubucda ah, wax soo saarka kasta oo ah 1 tan oo ah tuubbada korantada ee korantada, spaphite electrode 10 M

Cayimid

Ibta I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I IIGO MACLUUMAADKA XUQUUQDA AADANKA, MA AHAN in la jebiyo, iyo gudbinta hadda ee wanaagsan.

| Magac | Cutub | Dhexroorkii magacaabay | ||||||

| Uhp ultra-awood sare | HP SuperStong | Awoodda caadiga ah ee RP | ||||||

| ≤400 | ≥350 | ≤400 | ≥350 | ≤300 | ≥350 | |||

| Caadidsan | Koryaal | Μω · m | ≤5.5 | ≤6.5 | ≤8.5 | |||

| Ib naas | ≤4.5 | ≤5.5 | ≤6.5 | |||||

| Xoog dabacsan | Koryaal | Markhaati | ≥11.0 | ≥10.5 | ≥9.8 | ≥8.5 | ≥7.0 | |

| Ib naas | ≥20.0 | ≥16.0 | ≥15.0 | |||||

| Modulus laastikada | Koryaal | GPA | ≤14.0 | ≤12.0 | ≤9.3 | |||

| Ib naas | ≤18.0 | ≤16.0 | ≤14.0 | |||||

| Cucid | Koryaal | g / cm3 | ≥1.66 | ≥1.67 | ≥1.62 | 1.6 | ≥1.53 | ≥1.52 |

| Ib naas | ≥1.75 | ≥1.73 | ≥1.69 | |||||

| Isugeynta ballaarinta kuleylka | Koryaal | 10-6 / ℃ | ≤1.5 | ≤2.4 | ≤2.9 | |||

| Ib naas | ≤1.4 | ≤2.2 | ≤2.8 | |||||

| Dambas | % | ≤0.3 | ≤0.3 | ≤0.5 | ||||

Sifooyinka gaarka ah ee warshadaha

| Caabbinta (μω.m) | 4 - 9 micro |

| Cufnaanta muuqata (g / cm³) | 1.58 - 1.76 g / cc |

| Xoogga dabacsan (n / ㎡) | 9.5-11.0.0 MPA |

Sifooyinka kale

| Meesha asalka ah | IsagaBei falansan, Shihine |

| Magaca sumcadda | heyuan |

| Nambarka moodalka | RP, HD, HP, SHP, UHP |

| Teeb ku qorid | Xannibaadda elektrode |

| Isticmaal | Samaynta birta |

| Dherer | 1600 ~ 3000mm |

| Heer u qaybin | UHP (Awoodda sare ee Ultra) |

| Ballaarinta kuleylka | 1.5 - 2.8 x10-6 |

| Midab | Madoow |

| Isticmaal | Flace arc foornada (eaf) soosaarka birta |

| Weynaan | Cabir ahaan |

| Cucid | ≥1.52 |

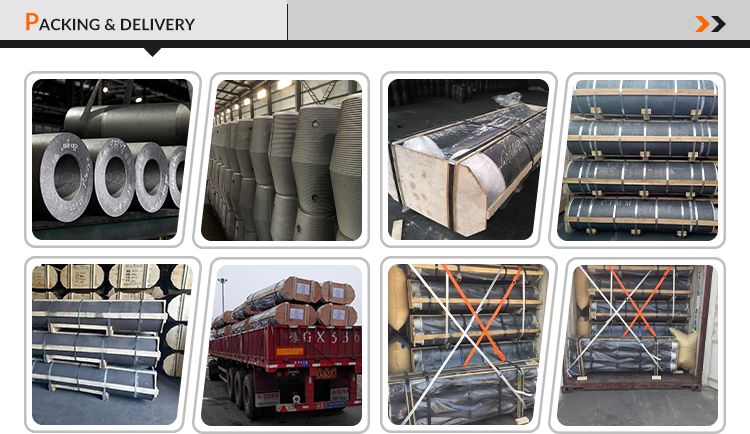

Baakadaha iyo dhalmada

| Faahfaahinta baakadaha | Baakadaha dhoofinta caadiga ah ama sida laga soo xigtay shuruudaha macaamiisha |

Awoodda sahayda

| Awoodda sahayda | 100 TON / TONS MAALMAHA MAALMAHA RONGRENGRENGROST |

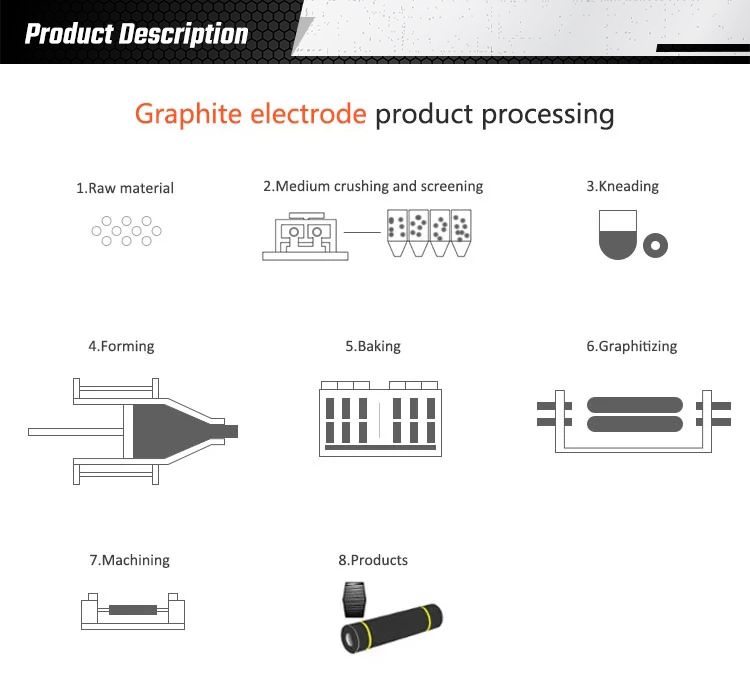

Nidaamka wax soo saarka oo faahfaahsan

Xirmooyinka & Gaarsiinta