Wax soo wadaban

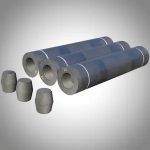

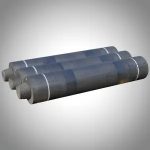

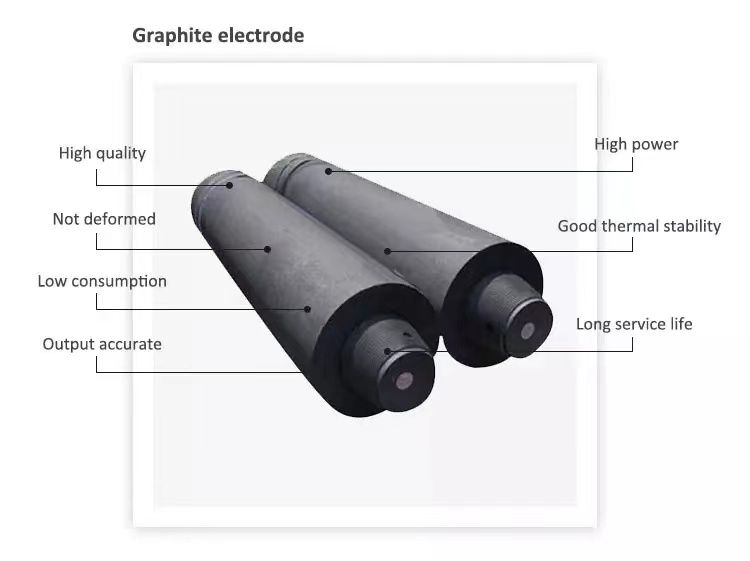

Nabarrada Electrode Nictors

1.low iska caabbinta korantada

2. Cufnaanta sare

3. Wadahadal koronto oo wanaagsan

4. Awoodda ka hortagga sareeya

5. Sax sax ah saxsanaanta

6. Sulfur hoose iyo dambas hooseeya, ha siin birta had iyo jeer wasakhda ah

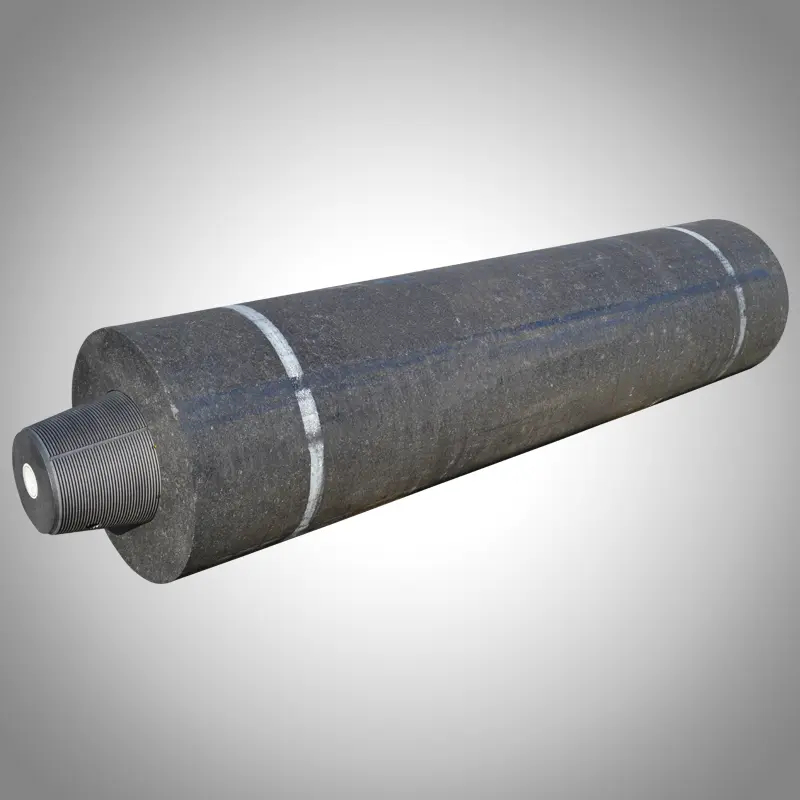

Electrode-ka garaafka ayaa noqon doona walxo heerkul sare ah, xudunta ka kooban batroolka coke, tar coke sida buufin, dhuxul cabir ahaan. Waxaan u soo saareynaa cudurka ibta gacmaha gapphite iyo ibta naaska. Cilmiga cudurka garaafka waxaa lagu gartaa iska caabin yar, wajah wanaagsan oo koronto ah iyo wanaajinta kuleylka, iska caabbinta heerkulka, iwm.Comic-ka, waxaa loo qaybin karaa koronto koronto oo caadi ah, awood sare Koobka korantada ee garaafka gacanta.

Tilmaamaha Elektaroonigga garaafka

1.low iska caabbinta korantada

2. Cufnaanta sare

3. Wadahadal koronto oo wanaagsan

4. Awoodda ka hortagga sareeya

5. Sax sax ah saxsanaanta

6. Sulfur hoose iyo dambas hooseeya, ha siin birta had iyo jeer wasakhda ah

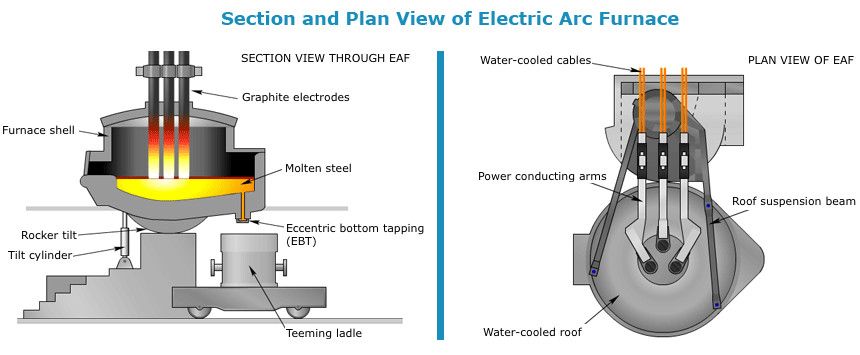

Adeegsiga qalabka korantada garaafka

Afka qalabka garaafka ee garaafka waxaa badanaa loo adeegsadaa nawaaqyada landle, foornada korantada-arc-arc ee foornada, foornada fosfooraska huruud ah, foornada warshadaha ama naxaasta dhalaalaysa. Waqti xaadiriyaan waxa kaliya ee la heli karo ee leh heerarka sare ee wada-shaqeynta korantada iyo awoodda sii wadida heerarka ugu sarreeya ee kuleylka ayaa ka soo baxa korantada sicirka ah, in la hubiyo in arjiga korantada uu kaamil yahay. Electrods elektarooniteyada ayaa sidoo kale loo isticmaalaa in lagu nadiifiyo birta ku yaal leyle foornooyinka iyo geedi socodka kale ee ku dhaca.

1.Marka loo adeegsaday wax soo saarka birta ee ARC (EAF) wax soo saarka birta;

2.feeyaha foornada ukunta; loogu talagalay foornada adkeysiga;

3.Waayo soo saarista alaabada garaafka sharaxaada;

4.Waa wax soo saarka alaabta garaafyada qaabeeya;

5.Losso waxaa loo isticmaali karaa foornootor u caabbian;

6.Waayo soo saarista alaabada qaabeeya ee garaaca;

Cayimid

| Magac | Cutub | Dhexroorkii magacaabay | ||||||

| Uhp ultra-awood sare | HP SuperStong | Awoodda caadiga ah ee RP | ||||||

| ≤400 | ≥350 | ≤400 | ≥350 | ≤300 | ≥350 | |||

| Caadidsan | Koryaal | Μω · m | ≤5.5 | ≤6.5 | ≤8.5 | |||

| Ib naas | ≤4.5 | ≤5.5 | ≤6.5 | |||||

| Xoog dabacsan | Koryaal | Markhaati | ≥11.0 | ≥10.5 | ≥9.8 | ≥8.5 | ≥7.0 | |

| Ib naas | ≥20.0 | ≥16.0 | ≥15.0 | |||||

| Modulus laastikada | Koryaal | GPA | ≤14.0 | ≤12.0 | ≤9.3 | |||

| Ib naas | ≤18.0 | ≤16.0 | ≤14.0 | |||||

| Cucid | Koryaal | g / cm3 | ≥1.66 | ≥1.67 | ≥1.62 | 1.6 | ≥1.53 | ≥1.52 |

| Ib naas | ≥1.75 | ≥1.73 | ≥1.69 | |||||

| Isugeynta ballaarinta kuleylka | Koryaal | 10-6 / ℃ | ≤1.5 | ≤2.4 | ≤2.9 | |||

| Ib naas | ≤1.4 | ≤2.2 | ≤2.8 | |||||

| Dambas | % | ≤0.3 | ≤0.3 | ≤0.5 | ||||

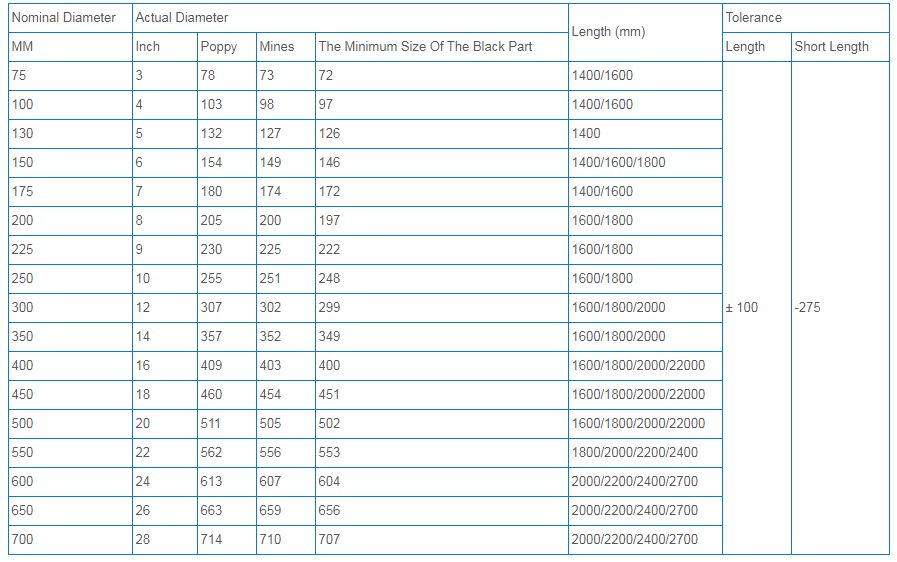

Dhererka & dhexroor & dhexroor la oggol yahay ee electrode electrode

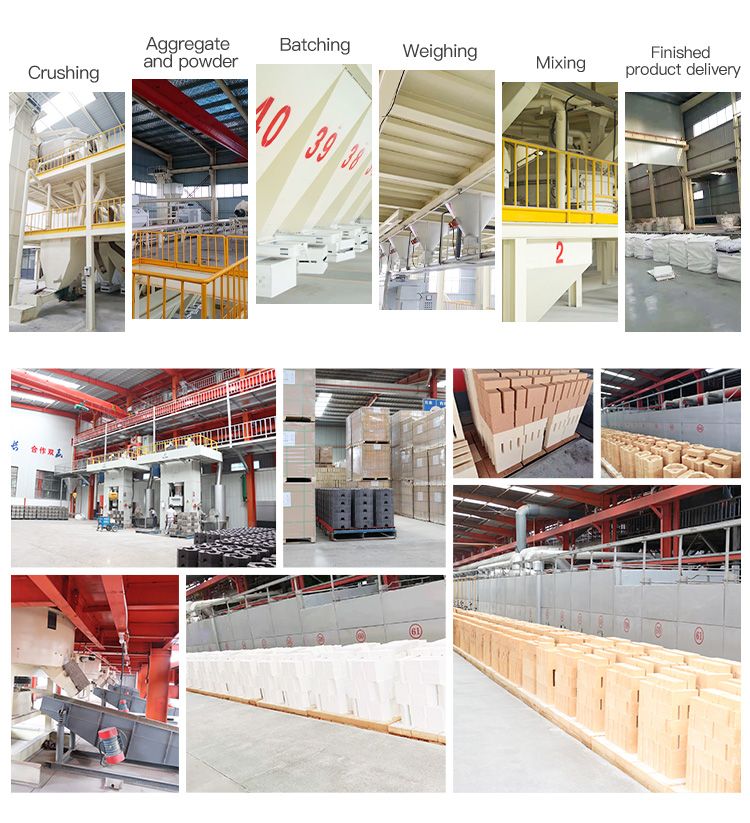

Aqoon isweydaarsi wax soo saar